Vibrating Motor

Vibrating Motor Manufacturer, Supplier, and Exporter in India

Mitool India is a distinguished Vibrating Motor Manufacturer, Supplier, and Exporter in India, offering top-notch Electromagnetic Vibrating Motors and Unbalanced Vibrating Motors designed for various industrial applications. Located in Ambarnath MIDC, Thane, Maharashtra, our advanced manufacturing facility ensures premium quality and high-performance vibrating motors tailored to meet the specific needs of industries like mining, construction, food processing, pharmaceuticals, and more.

Understanding Vibrating Motors

• Vibrating motors are electromechanical devices that transform electrical energy into mechanical vibrations, facilitating movement and material handling in industrial applications. These motors are categorized into two main types:

1. Electromagnetic Vibrating Motors

Electromagnetic vibrating motors operate on the principle of electromagnetic induction, where a magnetic field is created by an alternating current passing through a coil, generating vibratory motion.

Key Features:

• Low Maintenance: Brushless design reduces wear and tear, ensuring durability.

• Precision Control: Adjustable vibration frequency and amplitude for customized performance.

• High Efficiency: Minimal energy losses for optimal output.

2. Unbalanced Vibrating Motors

Also known as eccentric mass vibrator motors, these function through centrifugal force generated by rotating unbalanced masses, producing continuous vibrations essential for various applications.

• Key Features:

• Robust Construction: Built for heavy-duty operations and harsh environments.

• High Torque Output: Eccentric masses generate powerful vibrations.

• Versatile Applications: Suitable for screening, compaction, and material handling.

Applications of Vibrating Motors

Our high-quality vibrating motors are extensively used across multiple industries:

1. Cement Industry

• Material Handling: Efficient movement of raw materials such as limestone and sand.

• Screening: Ensures uniform separation of cement particles.

• Silo & Hopper Discharge: Prevents blockages, ensuring smooth material flow.

2. Power Industry

• Coal Handling: Aids in transportation and screening of coal for power plants.

• Ash Handling: Facilitates easy disposal and recycling of combustion residues.

3. Construction Industry

• Concrete Compaction: Eliminates air pockets for stronger concrete structures.

• Soil Compaction: Ensures stable foundations for buildings and roads.

4. Foundry Industry

• Sand Casting: Enhances molding sand compaction for precise castings.

• Shakeouts: Separates sand molds from finished castings efficiently.

5. FMCG Industry

• Product Sorting & Grading: Categorizes products by size, weight, and shape.

• Packaging Assistance: Ensures optimal filling and compacting of products.

6. Plastic Industry

• Material Conveying: Facilitates smooth flow of plastic granules and powders.

• Screening & Recycling: Aids in sorting and refining plastic waste for reuse.

Unbalanced Vibrator Motors

Our unbalanced vibrator motors are engineered for superior performance and reliability. These motors feature:

• Heavy-duty cylindrical roller bearings resistant to vibrations.

• High-quality resin impregnated windings ensuring enhanced durability.

• Dust-tight and watertight enclosures with rubber O-ring end shields.

• Vibration-resistant terminal board for secure wiring.

• Adjustable out-of-balance weights for precise force control.

Technical Specifications:

• Centrifugal Force: Ranges from 1830 to 122850 N.

• Working Moment: 3.7 to 2250 kgcm.

• Suitable for Vibrator Units: 3.5 to 5500 kg.

• Power Supply: 415V, 3-phase, 50Hz.

• Rated Output: 0.3 to 8.56 kW.

• Ambient Temperature: Up to 60°C.

• Enclosure Type: IP55.

• Insulation Class: 'F' Class.

Power Supply and Connection

Our vibrating motors are powered by a three-phase system using flexible copper conductor cables. Connection can be established via a common contactor with auxiliary contacts for interlocking. We highly recommend utilizing a circuit breaker when multiple motors are used to prevent oscillation and ensure safety.

For advanced performance and longevity, our motors can be connected using a DC braking unit, reducing oscillation and bringing the motor to a standstill in just 1-2 seconds, preventing unnecessary mechanical stress.

Why Choose Mitool India for Vibrating Motors?

Mitool India stands out as a leading Vibrating Motor Manufacturer, Supplier, and Exporter due to:

• State-of-the-Art Manufacturing Facilities ensuring precision engineering.

• Customized Vibrating Motor Solutions for diverse industry needs.

• Stringent Quality Control Measures ensuring durability and reliability.

• Comprehensive After-Sales Support for seamless operation and maintenance.

Contact Us

For premium-quality Vibrating Motors, Electromagnetic Vibrating Motors, and Unbalanced Vibrating Motors, trust Mitool India. Contact us today to discuss your industrial requirements and get the most efficient solutions tailored to your application.

We, Mitool India is engaged in manufacturing and providing Unbalance Vibrator Motors which are asynchronous AC Motors with pairs of centrifugal weight fitted to the ends of the motor shafts. These kind of Vibrator Motors are robust, having cylindrical roller Bearings and highly stable under load. End Shield fitted with rubber 0 rings to give dust tight and watertight enclosure. The size of the unbalance and amplitude oscillation by the working unit which can be adjusted by moving the centrifugal weights when the motor is at a standstill.

| Centrifugal force range | : | from 40to 35000 N. |

| Working moment | : | from 1 to 631 kgcm. |

| Suitable for Vibrator units with useful weight range | : | from 1 to 1440 kgs |

| .PowerSupply | : | 415 Volts,3 phase, 50 hz. |

| Rated output | : | 0.1 to 2.3 kw |

| Ambient temperature | : | upto 60°C |

| Type of enclosure | : | IP55 |

| Insulation Class | : | 'F' Class |

• Vibration resistant, high-quality resin impregnated winding.

• Easy to handle and repair.

• Quite running and no maintenance required.

• Durable, reliable and give high performance.

• Robust terminal board, cable wire solid in vibration resistant synthetic resin.

• Coal, Lignite, Salt, Synthetic, Rubber, Fertilizers & Chemicals.

• Well equipped with special profile bearings, high carrying load and increased bearing work.

• Used as drive-unit for Vibrating Machines like Bin-Dischibratory Motorarging, bulk-product conveying (horizontal or vertical both) sizing or course, screening, vibrating feeders, vibrating grizzly feeders, paper jogger, vibrating tables, concrete hoppers, vibrating conveyors, de-watering, compaction, discharge-aid in bins and silos.

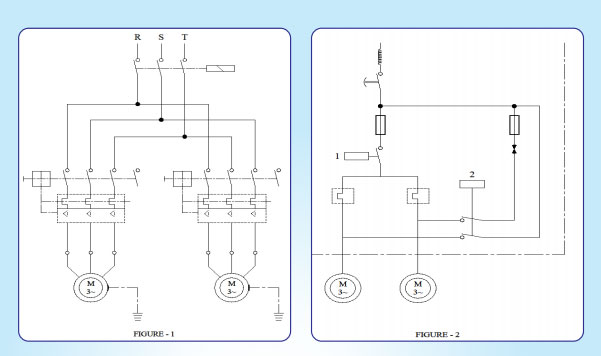

Vibration motors are connected to the three-phase system with flexible copper conductor cable. The connection can be effected as per (fig. 1) in the easiest manner by means of a common contactor which must be interlocked by means of auxiliary contacts. We Mitool India, strongly recommend the use of a circuit breaker wherever two motors are used.

On the other side with the latter connection, considerable oscillation occurs on the disconnection of the equipment due to the fact that resonant frequencies of the support springs will have a comparatively slow run through especially at a time when the trough is empty and the bulk material is absent. A connection of the motors via a broken unit (Fig, 2) with which the motors can be brought to a standstill through d.c. breaking in a period of one to two seconds is recommendable.

As a drive for : Vibrating conveyors, Conveyor troughs and tubes, Conveyor sections,

As a Vibrator for : Silos, Bins, Deflection, grids, Filters, Filling plant, Chutes, Gravity pipes.